ONGUARD Approved by ICC-ES to Guarantee Code Compliance

ONGUARD promises unparalleled earthquake risk protection for the aboveground storage tank industry. We maintain the industry’s trust through the accreditation and testing of our anchors to ensure they meet the rigorous performance and quality standards our customers demand.

OG PRO MkIII anchors were evaluated by ICC-ES for International Building Code compliance, and the ductile elements regularly undergo materials tensile testing to verify high precision design performance.

ICC-ES Accreditation

ICC Evaluation Service, LLC (ICC-ES), a subsidiary of the International Code Council, conducted an Evaluation Report on the OG PRO MkIII Anchor Series (ESR-4564) in 2021. This type of report verifies that “new and innovative building products comply with code requirements”.

This Evaluation Report proves that ONGUARD anchors function exactly as intended under cyclic loading.

The OG PRO MkIII anchors were reported to be in compliance with the 2018 and 2015 International Building Codes (IBCs) and the 2020 City of Los Angeles Building Code (LABC) by the International Code Council Evaluation Services (ICC-ES).

Our anchors are manufactured under an approved Quality Control Program with inspections performed by ICC-ES on a regular basis.

Lab Tensile Testing

ONGUARD uses a capacity design approach for OG PRO anchors, allowing the yielding of a ductile pin. Since this element is intentionally the weakest point of the anchor, it is critical that its real ultimate strength is known to create the most efficient design possible and protect the integrity of the rest of the system.

ONGUARD anchor pins are tensile tested in an internationally accredited laboratory in accordance with ASTM A370. This tensile testing allows the ultimate strength of OG PRO MkIV anchors to be tuned to a precision of one tenth of a kiloNewton (0.002 kipf).

This level of precision gives the ONGUARD system an advantage in being able to minimize the strength requirements of all elements of the system while maintaining all code and safety requirements.

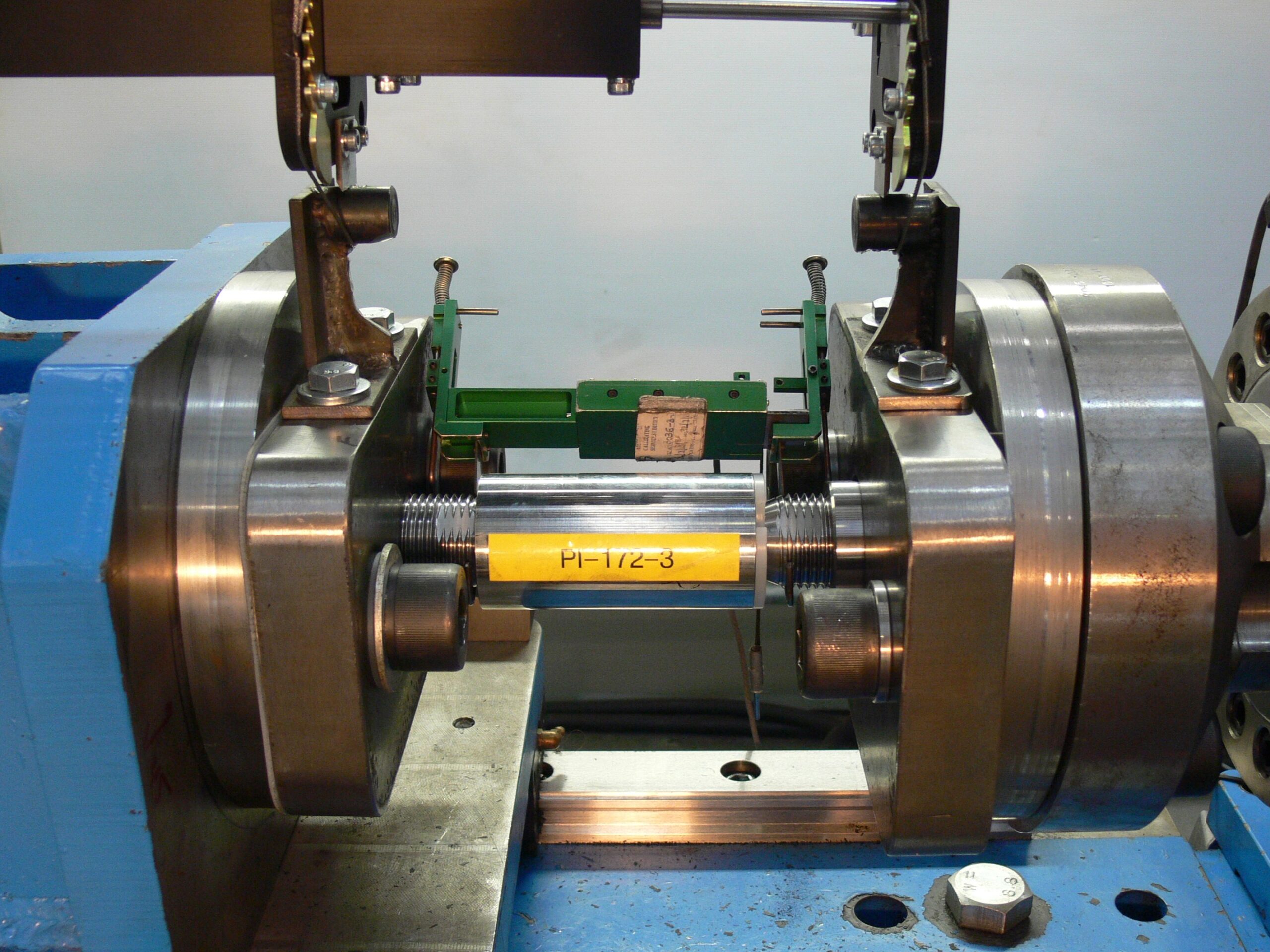

Figure 1: Onguard MKIII anchor mounted in cyclic test rig prior to testing

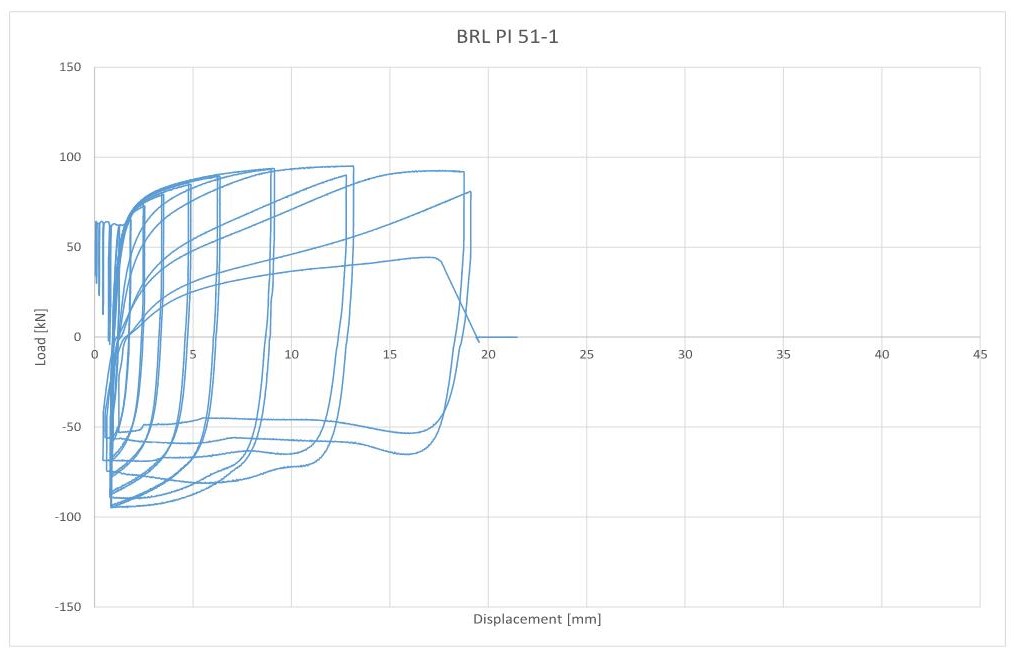

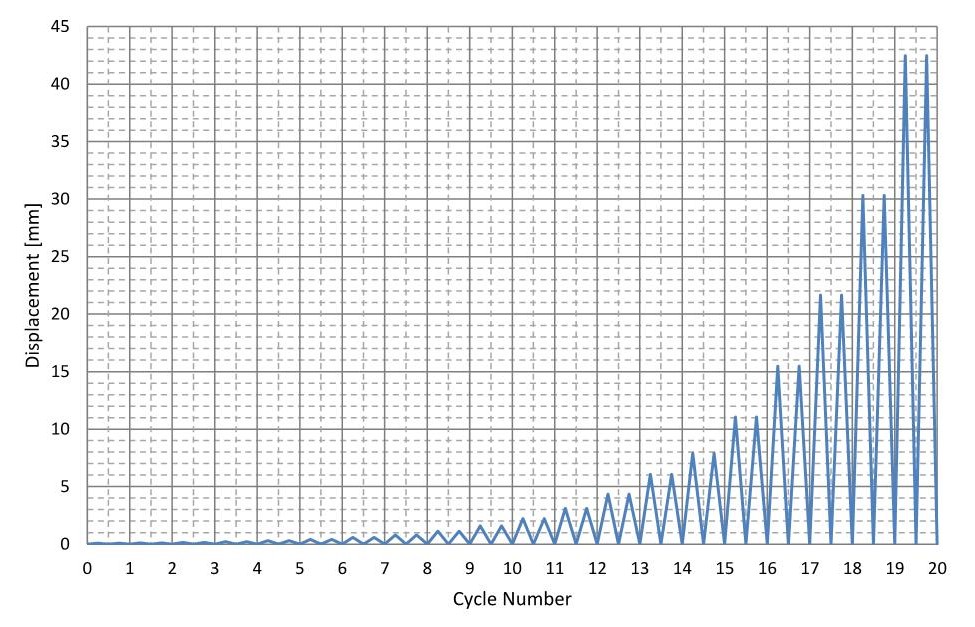

A range of anchor sizes were tested under quasi-static cyclic loading, verifying their performance in tension and compression. Prototype testing was completed in accordance with FEMA 461 (2007) using a displacement-controlled loading protocol.

Figure 2: Load displacement response of one of the tested Onguard OG PRO MKIII anchors

Figure 3: FEMA 461 loading protocol used to test the Onguard OG PRO MKIII anchor

In Conclusion

ONGUARD’s system testing ensures our designs are held to international standards of compliance and provide unparalleled levels of efficiency, performance, reliability, and quality.

Contact ONGUARD today for more information.

References